1. Definition and Construction of Synchronous Generators

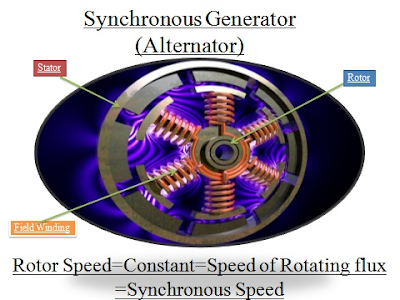

Definition:

- A synchronous generator, also known as an alternator, is a device that converts mechanical energy into electrical energy in the form of alternating current (AC). It operates at a constant speed in synchrony with the frequency of the supply current.

Key Components and Construction:

- Stator: The stationary part of the generator containing the armature windings where the output AC is produced.

- Rotor: The rotating part of the generator that creates a rotating magnetic field. It is typically an electromagnet powered by direct current (DC).

- Exciter: Provides the DC current to the rotor windings.

- Prime Mover: An external mechanical force (e.g., steam turbine, water turbine, internal combustion engine) that drives the rotor.

- Bearings: Support the rotor and allow it to spin freely.

- Frame: The casing that holds all components together and protects the generator.

2. Working Principle of Synchronous Generators in Bullet Points

- Magnetic Field Generation: DC current supplied to the rotor winding creates a magnetic field.

- Rotor Rotation: The prime mover rotates the rotor.

- Electromagnetic Induction: As the rotor spins, the magnetic field rotates around the stator.

- AC Generation: The rotating magnetic field induces an alternating voltage in the stator windings according to Faraday's Law of Electromagnetic Induction.

- Synchronous Speed: The generator operates at a constant speed (synchronous speed) determined by the grid frequency and number of poles on the rotor.

3. Supplying DC Power to the Rotor of a Synchronous Generator

- Slip Rings and Brushes: DC power is often supplied to the rotor via slip rings and brushes, which maintain electrical contact with the rotating rotor.

- Brushless Exciters: Modern generators may use a brushless exciter, where an AC exciter (a smaller generator) produces AC, which is rectified to DC by rotating rectifiers directly on the rotor shaft.

- Static Exciters: In some systems, a static exciter uses stationary electronics to control and supply DC current to the rotor through slip rings.

4. Operating a Synchronous Generator Alone

- Prime Mover Speed: Ensure the prime mover can maintain the generator at its synchronous speed.

- Excitation System: Ensure the excitation system is functional and can supply the necessary DC current to the rotor.

- Voltage Build-Up: Gradually increase the excitation to build up the terminal voltage to the desired level.

- Load Connection: Connect the electrical load ensuring the generator can handle the load without dropping out of synchrony.

- Monitoring: Continuously monitor voltage, frequency, and load to maintain stable operation.

5. Parallel Operation of Synchronous Generators

- Synchronizing Conditions: Ensure both generators have the same voltage magnitude, frequency, and phase sequence.

- Synchronizing Equipment: Use synchronizing lamps or a synchroscope to match the phase angle of the incoming generator with the operating system.

- Synchronization Procedure:

- Bring the incoming generator up to the correct speed.

- Adjust the excitation to match the voltage.

- Use the synchroscope to close the breaker at the precise moment when the phase angles match.

- Load Sharing: After connection, adjust the governors and excitation systems to ensure proper load sharing between generators.

6. Key Differences between Synchronous Generators and Motors

Synchronous Generators:

- Function: Convert mechanical energy to electrical energy (AC).

- Prime Mover: Driven by external mechanical force.

- Application: Power generation in power plants.

- Operating Speed: Always operates at synchronous speed.

Synchronous Motors:

- Function: Convert electrical energy to mechanical energy.

- Prime Mover: Uses supplied AC power to generate mechanical torque.

- Application: Industrial applications requiring constant speed operation.

- Operating Speed: Runs at synchronous speed regardless of the load.

Key Distinct Characteristics:

- Generators output electrical power, while motors consume electrical power to produce mechanical work.

- Generators are generally used in power generation, whereas motors are used in various industrial and commercial mechanical drives.